Sparrowhawk, the Dream

- Evanita W. Montalvo

- Aug 11, 2021

- 6 min read

Updated: Apr 30, 2024

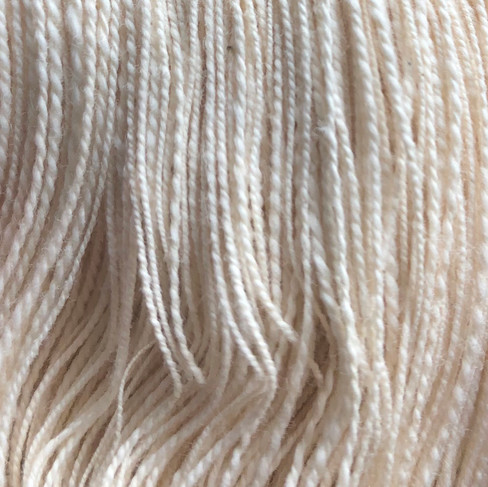

While putting the Sparrow through its paces James decided to push it to the limits with spinning cotton which requires high speeds and super low take up. I quickly followed as well with cotton and we both noted that Sparrow was voraciously eating it up as if it was a delicacy. James of course ran full tilt at 100% speed with his cotton spinning which is approximately 2,040 RPM! Here's a peek at James's cotton spinning.

Meanwhile I was sprinting at about 70% which to me was crazy fast. I eventually worked my way up to 90% speed which is approximately 1,830 RPM. Here are some of my cotton spinning. I've never been so happy spinning cotton as I was with Sparrow and deemed it my Cotton Wheel at least until Dave made something that was even more suited towards cotton. I even amassed a ginormous pile of cotton all waiting to be spun on this wee little wheel.

While I need some time to work my way up to faster speeds James still felt the need for more speed and so the dream of Sparrowhawk developed. We wanted something small and yet mighty with plenty of speed for cotton and production spinners. Ever since then there have been whispers of what Sparrowhawk will be like and we have eagerly awaiting to see what Dave had in store for the cheetah of espinners! On August 6, 2021 Dave finally publicly shared the flyer for Sparrowhawk on the Daedalus Facebook Group. What follows is some of the conversation that Dave shared on this post.

Them: If you had to design a flyer capable of 8k rpm to be used non stop above 4k rpm, what would it look like? Me: This. Coming soon. - August 6th, 2021

I make sure nothing happens at 2x design speed, to ensure safety. Goal for proto testing at 4200rpm. - August 6th, 2021

There is absolutely NO aesthetic compromises. Every millimeter was considered with an aeronautical eye, to keep the bobbin as fast as it can go (and be as closely synced to the flyer for low take up needed). The aerodynamic coupling is truly the beauty in this design, using the air in our favor to help push the bobbin along. I showed on a bench with Starling V1 that the coupler worked, and I took it up a notch with Sparrow. Sparrowhawk's flyer is the end-game design of the aero coupling design detail. But the sturdiness of the dual disc flyer blades, coupled with 3.6g short carbon fiber arms... my math says it won't explode at over 8krpm which makes me sleep well knowing they will be used at 4.2krpm. - August 6th, 2021

Just to be clear... This design is not for everyone. It's not even for some. It's for a few highly skilled souls that constantly push me to improve my designs. If you are a new spinner, move along (you will not be happy). Because this is a racehorse that doesn't know how to trot. It's most useful speed envelope starts beyond what the normal hobby spinner considers comfortable. I do not expect to sell many of these (it is not a money making pursuit). But rather I wanted to really use my aeronautical design experience to show how we can eliminate drag and friction where they hurt us, add it where they help, and end up with the best design I can fathom for a 4krpm thread spinner. - August 7th, 2021

4am. Hit 3200 with the"safe" gearing.. head was stable and as quiet as a sleeping cat. Motor was begging for more work to do. No roar of impending doom. New gearing for tmrw to test, target of 4100rpm. - August 8th, 2021

Hit 4k tonight with intended gearing. Measured with guides at the end of the arms - checked splay at 3mm (with a design goal of under 5mm). 2mm of the splay was calculated to be arm flex (deflection under load data) leaving 1mm at the arm tip resulting from flyer frame allowance (which is unbelievably stout evidently. Maybe it's 2mm IDK). Motor temp was up about 10F over ambient, with a working range of about 60F over ambient (leaves a lot of room for the big motor to do work from here). A new air cooling impeller was designed for this gearing and is producing twice the flow of previous designs, and without any significant extra load on the motor. And it looks BOSS as heck. Motor and maiden bearing still need further break in before numbers (and temps) stabilize. Experience is truly serene - at 50% speed (Sparrow at max), the head is basically silent. At the full 4krpm, it's sounds a little angrier than Sparrow, kinda like a Magpie at full tilt. 700rpm is technically achievable (mechanically) but I'm not sure its viable to be able to operate the motor that slowly until we do some spinning. 1000rpm, seems easily doable (at this point). - August 8th, 2021

Running at 4020rpm, steady as a metronome, with guides and bobbin mounted (no cheating). Motor brushes are still breaking in after 8hrs of full speed, but now motor shows only 6F over ambient, which is unbelievably cool. Let's say I'm happy with the motor choice here. I've ordered some very high end ceramic bearings to test here, but the quality conventional bearings used now are well within operating temp range and that temp is dropping too, as it breaks in. I just want the best, not "good enough." - August 9th, 2021

Well, if I'm trying to over engineer any part, it's the motor pinion (pulley). 6061 aluminum, integral motor cooling impeller outfitted with proper nose cone and velocity stack. Oh, and this one is balanced so it provides the same direction and amount of airflow in either motor direction, just FYI. - August 9th, 2021

I really need to apologize to all of you... I've made a mistake. Sparrowhawk can go all the way down to 400rpm with no problems whatsoever!!!!! Operated smoothly with all the torque from that big ol' motor. It passed the operational (spinning) test with flying colors from 400-1000rpm. It also passed the heat test at these speeds under simulated tremendous load. So all that crap I said about not for everyone etc was because I genuinely thought it had no chance of these speeds. It's not really still "for everyone" but now I can confidently say a novice can use it with ease. This is a wonderful surprise for me! Another passed test as a huge surprise - I have not been able to heat anything up at all, even at 100% speed and HEAVY tension on the 3mm Kevlar brake band... neither the motor nor the aluminum brake drum were anything more than "barely perceivably warm." During its first full speed torture test, pulled no punches and couldn't even make it sweat! This is HUGE! An abuse-proof 4krpm spinner! - August 10th, 2021

Okay. Decided to shoot the nitrous to it last night. Held steady at.....6090 rpm. That's a SIX. - August 10th, 2021

100th comment! I'm calculating the linear speed of the flyer arms, on a 4" span (102mm) at 4krpm, as 47.6 miles per hour. Can I get a double check? Because I tested Magpie Ultra at 70mph+ tip speeds and was about my limit (and that was with a slightly deeper engagement distance because of the lower rpm, and much higher momentum). It'll still need a disclaimer about safe use with "lathe" type rules. No long sleeves, hair must be pulled back, no loose objects within 18", and definitely don't place any unsecured fiber next to it. The air immediately around the flyer is a mini tornado, and the motor cooling pinion impeller now can draw air from a foot away! So a clean stable work surface - no spinning at 4k in bed with fluffy snoozing beside. It's a serious tool at those speeds, but evidently doesn't mind idling for a leisurely walk too. Motor mount now has an extended shroud to encompass the pinion, and channel the exhaust air down the sides of the motor, exiting the rear. (I'm really having fun with the thermo and fluid dynamics involved here!) - August 10th, 2021

To read more of the group conversation on these new developments stop by our Daedalus Spinners Group on Facebook. Stay tuned for more Sparrowhawk news and don't forget to watch and participate in the Live Q&A on our Facebook group Sat August 14, 2021 @ 5 pm EDT USA.

To Subscribe to our Blog and be able to leave comments click on the Login/Sign Up button. We currently have it set up for sign ups requiring approval to mitigate potential spam. Happy Spinning!

Evanita

Comments